Fiber lasers:

Laser amplifiers or the solid-state lasers where the light travels due to the total internal reflection in a single-mode optical fiber are known as fiber lasers. Because of the guidance of the light, very long gain areas are allowed to provide good cooling conditions; The fiber has a high surface-area-to-volume ratio that allows for efficient cooling. Furthermore, the properties of fiber’s waveguiding start decreasing the thermal distortion of the beam. The most common active species in such lasers are ytterbium and erbium ions.

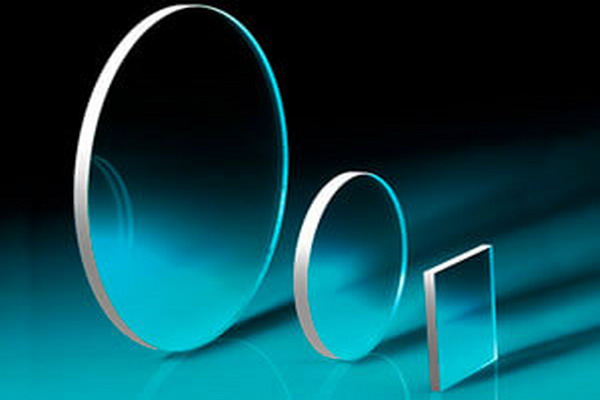

Quite often, the design of the fiber lases by keeping in mind the double-clad fiber. This type of fiber consists of a fiber core, an inner shell, and an outer shell. The indices of the three concentric layers are chosen so that the fiber core acts as a single-mode fiber for laser emission while the outer cladding acts as a highly multimode core for the pump laser. This allows the pump to propagate a large amount of power inside and through the inner region of the core which is active, while it still has a high numerical aperture (NA) to have easy launching conditions. The process of optical plastics custom lens design requires the use of industrial lasers optics and optical transmission windows.

By creating a fiber disk laser, the pump light can be used more efficiently, or a stack of such lasers. One of the biggest disadvantages of fiber lasers is that the light intensity in the fiber cannot be so high that optical nonlinearity induced by the strength of the local electric field can take effect and prevent laser operation and/or cause physical destruction of the fiber. This whole effect is known as photodarkening. The cooling is not efficient, in the case of bulk laser materials and it becomes quite difficult to separate the effects of photodarkening from the thermal effects, but the experiments in fibers display that the photodarkening can be attributed to the formation of long-living color centers.

Chemical lasers:

Chemical lasers use chemical reactions as a power supply which permits a large amount of energy to be released quickly. Such very high-power lasers are of particular interest to the military, although continuous wave chemical lasers have been developed at very high-power levels, which are fed by gas streams and have few industrial applications. For example, in the deuterium fluoride laser (3800 nm) and the hydrogen fluoride laser (2700 – 2900 nm) the reaction is the combination of deuterium or hydrogen gas with combustion products of ethylene in nitrogen trifluoride.